联系-新盛公司客服中心【微-64881330】

新盛公司官方游戏网址 www.xs8617.com 联系-新盛公司客服电话-【134-0888-8125】-企鹅微信同步-【64881330】新盛公司客服24小时在线,【公司直属客服】【公司直属开...

Control Method

I. Introduction

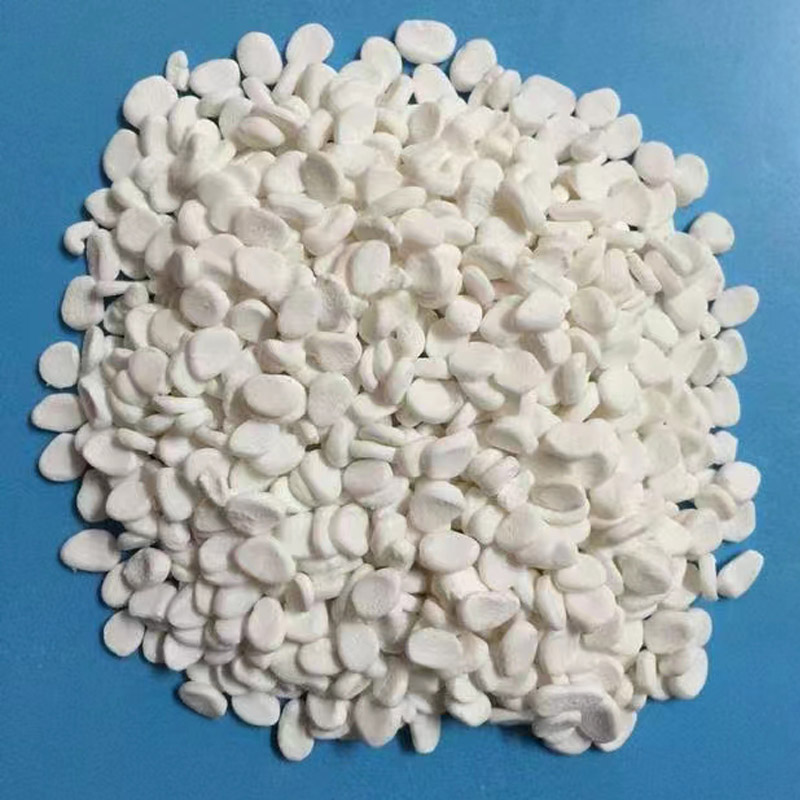

Name: PE Weather-Resistant Flame Retardant Masterbatch

Model: PEGL05

Appearance: White Granules

Addition Level: 15%

Environmental Standard: ROHS

Flame Retardant Rating: Self-extinguishing upon removal of ignition source.

Application Scope: PE, EVA plastic flowers, plastic leaves, artificial turf, and other outdoor products requiring high UV resistance.

II. Advantages and Strengths

Utilizes a low-melting-point, eco-friendly bromine-antimony flame retardant system, offering good flowability and high flame retardant efficiency.

Suitable for UV-resistant outdoor products; does not fade even after years of prolonged sun exposure, possessing excellent thermal stability and light stability.

Low density with good compatibility with base resins.

High molecular weight ensures product stability, preventing issues like blooming, exudation, or whitening.

III. Packaging / Storage

25 kg/bag, paper-plastic composite packaging.

Transport as general chemicals.

Store in a dry, cool place. Protect from moisture and avoid direct sunlight.

IV. Product Specifications

Item | Quality Indicator |

Active Flame Retardant Content % | ≥ 70 |

Density g/cm³ | 1.20 |

Moisture Content % | ≤ 0.1 |

Volatiles % | ≤ 0.3 |

Melt Flow Index g/10min (200°C, 10kg) | 60 |

Melting Point °C | ≥ 130 |

Processing Temperature °C | ≤ 250 |

V. Application Examples

Product | LDPE% | HDPE% | Flame Retardant Masterbatch | Thickness | Flame Retardancy |

Blown/Cast Film | 88 | - | 12% PEGL04 | 100 µm (10丝) | Self-extinguishing |

Plastic Flowers, Injection Parts | 80 | - | 20% PEGL05 | 0.5mm | Self-extinguishing |

Extrusion Coating | - | 90 | 10% PEGL06 | 100 µm (10丝) | Self-extinguishing |

VI. Frequently Asked Questions (FAQ)

Q: What is the Melt Flow Index (MFI) of your masterbatch? Our base resin has an MFI of 70. We've tried many flame retardant masterbatches but couldn't achieve sufficient filling, and when we did, the color became lighter, and the weight per piece exceeded the limit.

A: Our flame retardant masterbatch has an MFI of up to 60 g/10min (200°C, 10kg), and requires a low addition level. It can fully meet your requirements.

Q: Is your masterbatch UV resistant? Our products are for outdoor use, and our customers have very high requirements for UV resistance.

A: Yes, our masterbatch is UV resistant and anti-yellowing, making it very suitable for outdoor products, maintaining color for 3 years without fading.

Q: Can your flame retardant masterbatch achieve self-extinguishing and a V-0 rating at a 17% addition level?

A: For thin plastic leaves, our PEGL05 masterbatch can achieve this. However, the optimal addition level may need slight adjustment up or down depending on the specific base resin, product design, and thickness.

Q: What precautions should be taken when using this masterbatch?

A: Although our PEGL05 masterbatch has high flame retardant efficiency, please note:

Do not add fillers such as calcium carbonate or talc, as this will significantly reduce or completely negate the flame retardant effect.

The selection of lubricants, antioxidants, and UV absorbers should be tested in advance to confirm they do not negatively impact flame retardancy before proceeding to large-scale production.

Special Notes:

Different PE and EVA resins have different MFI values, so the optimal addition ratio for the flame retardant masterbatch may vary. Conduct small-scale trials before full production.

PEGL04 and PEGL05 flame retardant masterbatches are not suitable for use with fillers such as talc or calcium carbonate, as this will cause a significant reduction or complete loss of flame retardant properties in the final product.

OnlineMessage

CN

CN EN

EN