联系-新盛公司客服中心【微-64881330】

新盛公司官方游戏网址 www.xs8617.com 联系-新盛公司客服电话-【134-0888-8125】-企鹅微信同步-【64881330】新盛公司客服24小时在线,【公司直属客服】【公司直属开...

Control Method

Introduction

The Decabromodiphenyl Ethane Masterbatch HX-Br produced by our company features a superior carrier, high active content, and excellent dispersibility. It can directly replace powdered Decabromodiphenyl Ethane in equal amounts without compromising flame retardant efficiency and complies with EU ROHS environmental requirements. After being uniformly mixed with the base resin, it can be directly used in extrusion or injection molding processes, making it simple and easy to use.

Table 1: Product Specifications

Indicator | HX-Br120 | HX-Br140 |

Product Name | Decabromodiphenyl Ethane Masterbatch | Decabromodiphenyl Ethane Masterbatch |

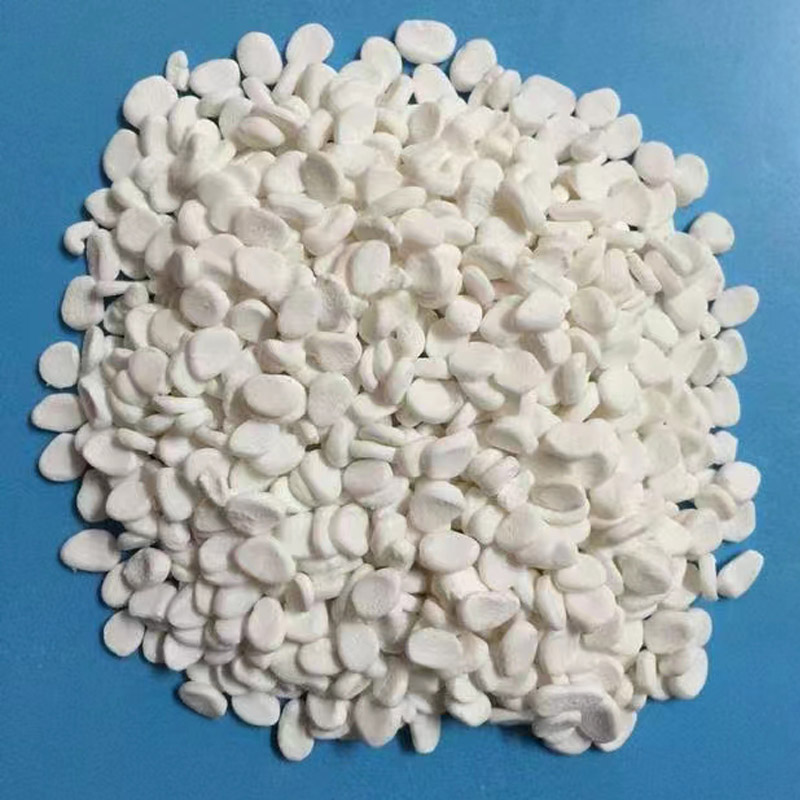

Appearance | White Granules | White Granules |

Carrier | / | EVA |

Flame Retardant Content % | ≥ 90 | ≥ 88 |

Addition Level % | 10-15 | 10-12 |

Moisture Content % | 0.05 | 0.05 |

Melting Point °C | 120 | 120 |

Table 2: Product Features

Model | Product Advantages |

HX-Br120 | Suitable for flame retardancy in Nylon, PBT, PP, and PC. Equally replaces powdered Decabromodiphenyl Ethane. |

HX-Br140 | Suitable for products like EVA, PE, ABS, HIPS, and rubber. Equally replaces powdered Decabromodiphenyl Ethane. |

Packaging / Storage

25 kg/bag, paper-plastic composite packaging.

Transport as general chemicals.

Store in a dry, cool place. Protect from moisture and avoid direct sunlight.

Friendly Reminder

The data provided above is for reference only. Due to various factors such as differences in end products, equipment, formulations, and the specific grade of raw materials selected, the optimal addition level of the flame retardant masterbatch may vary. It is necessary to conduct trials before using the masterbatch and proceed to mass production only after confirming normal performance.

OnlineMessage

CN

CN EN

EN