联系-新盛公司客服中心【微-64881330】

新盛公司官方游戏网址 www.xs8617.com 联系-新盛公司客服电话-【134-0888-8125】-企鹅微信同步-【64881330】新盛公司客服24小时在线,【公司直属客服】【公司直属开...

Control Method

Introduction

Due to the fine particle size, high viscosity, and severe dusting of antimony trioxide powder, it causes significant pollution in production areas and waste in production processes. In response to customer requirements, our company utilizes advanced equipment, fully enclosed production processes, and rational formulations and technologies to process antimony trioxide into HX-Sb masterbatch based on different carriers. This masterbatch features high antimony trioxide content, no pollution, no loss, good dispersibility, excellent compatibility, and can replace powdered antimony trioxide in equal amounts without reducing flame retardant effectiveness. It also exhibits good compatibility with various thermoplastic resins.

Furthermore, the masterbatch completely avoids the issue of severe skin itching caused by workers' allergic reactions to antimony trioxide dust. It complies with EU environmental standards such as ROHS, Reach, PAHs, and 2005/84/EC. After uniform mixing with resins, it can be directly extruded, making it simple and easy to use.

Table 1: Product Specifications

Indicator | HX-Sb220 | HX-Sb230 |

Product Name | Antimony Trioxide Masterbatch | Antimony Trioxide Masterbatch |

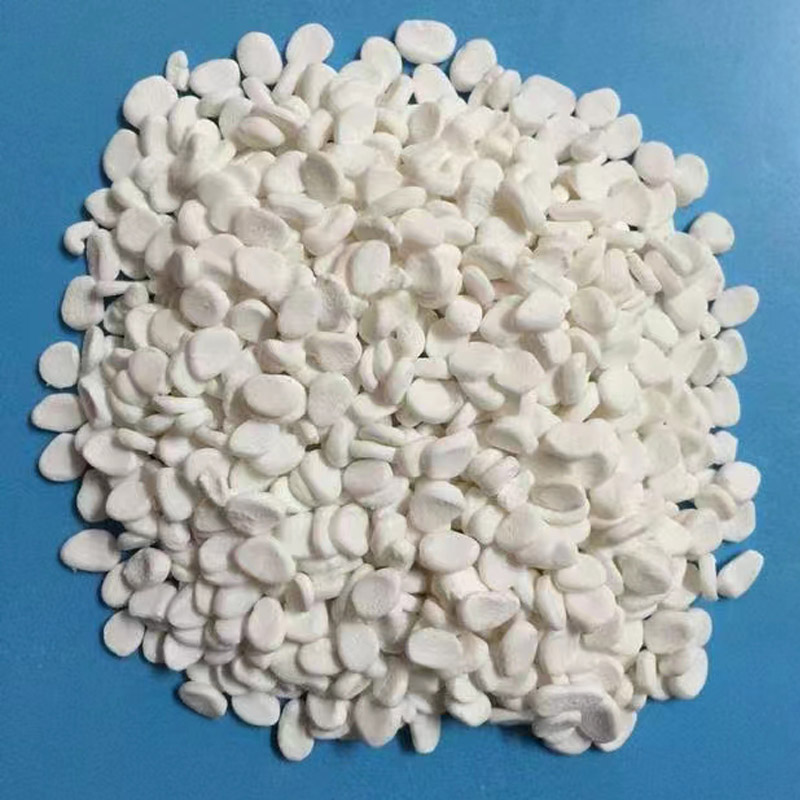

Appearance | White Granules | White Granules |

Carrier | Nylon/PBT-friendly Elastomer | CPE |

Flame Retardant Content % | ≥ 91 | ≥ 85 |

Addition Level % | 4-6 | 4-6 |

Density g/cm³ | 3.4 | 3.0 |

Table 2: Product Features

Model | Product Advantages |

HX-Sb220 | Suitable for products such as Nylon, PBT, PP, TPE, TPU, etc. Equally replaces powdered antimony trioxide. |

HX-Sb230 | Suitable for products such as PVC, ABS, HIPS, PE, etc. Equally replaces powdered antimony trioxide. When used in PVC profiles, it allows direct extrusion of required sheets, pipes, wires, etc., enabling continuous production without screen clogging. |

Packaging / Storage

25 kg/bag, paper-plastic composite packaging.

Transport as general chemicals.

Store in a dry, cool place. Protect from moisture and avoid direct sunlight.

Friendly Reminder

The data provided above is for reference only. Due to various factors such as differences in end products, equipment, formulations, and the specific grade of raw materials selected, the optimal addition level of the flame retardant masterbatch may vary. It is necessary to conduct trials before using the masterbatch and proceed to mass production only after confirming normal performance.

OnlineMessage

CN

CN EN

EN