联系-新盛公司客服中心【微-64881330】

新盛公司官方游戏网址 www.xs8617.com 联系-新盛公司客服电话-【134-0888-8125】-企鹅微信同步-【64881330】新盛公司客服24小时在线,【公司直属客服】【公司直属开...

Control Method

I. Introduction

Name: PC/ABS Toughened Flame Retardant Masterbatch

Model: PC/ABS803-T

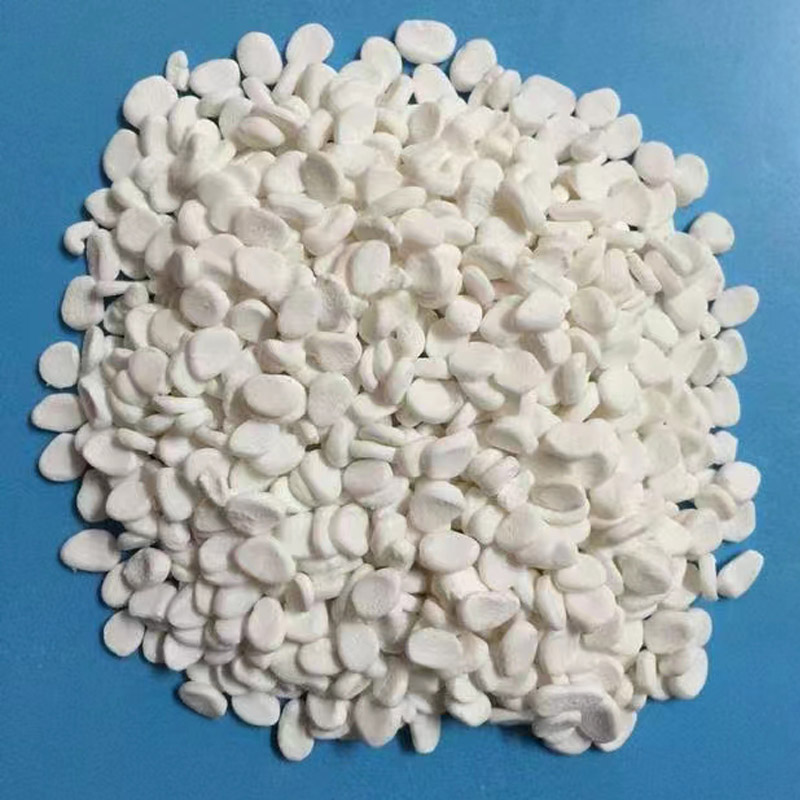

Appearance: White Granules

Addition Level: 6-7%

Environmental Standard: ROHS

Flame Retardant Rating: UL94 V-0

Application Scope: PC/ABS compounding, injection molding

II. Advantages and Strengths

Utilizes an eco-friendly bromine-antimony flame retardant system with high efficiency.

Offers excellent toughening and flame retardant effects with minimal impact on material properties.

Achieves a high flame retardant rating with little effect on heat deflection temperature.

Provides good low-temperature toughness.

Features UV resistance, heat oxidation resistance, non-blooming, and non-corrosiveness to molds, resulting in products with a smooth surface finish.

Widely used for applications requiring cold resistance (e.g., electricity meter casings) and thin-walled casings requiring ultra-high strength and superior flame retardancy.

III. Packaging / Storage

25 kg/bag, paper-plastic composite packaging.

Transport as general chemicals.

Store in a dry, cool place. Protect from moisture and avoid direct sunlight.

IV. Product Specifications

Item | Quality Indicator |

Active Flame Retardant Content % | 52 |

Density g/cm³ | 1.42 |

Moisture Content % | ≤ 0.1 |

Twin-Screw Processing Temperature °C | ≤ 240 |

Injection Molding Temperature °C | ≤ 260 |

V. Application Examples

Formulation | UL94 | Notched Impact (23°C) kJ/m² | Tensile Strength MPa | Elongation at Break % | Flexural Strength MPa | Flexural Modulus MPa |

Virgin Material (Flame Retardant) | — | 20.9 | 57.8 | 22.2 | 83.6 | 2451 |

PC/ABS + 5% PC/ABS802 | V0/1.6mm | 16.7 | 54.2 | 4.1 | 84.2 | 2487 |

PC/ABS + 8% PC/ABS803-T | V0/1.6mm | 20.3 | 52.2 | 21.8 | 78.0 | 2297 |

VI. Frequently Asked Questions (FAQ)

Q: What addition level of your PC/ABS803-T masterbatch is needed to achieve a V0 rating?

A: The required addition level is closely related to your base material. If the base material already has a high flame retardancy level but lost some during processing, adding 5% may suffice. Typically, customers use 7%. If the base material has poor or no inherent flame retardancy, the addition level will need to be higher accordingly.

Q: Our product requires bright colors and a V0 rating. Can we achieve this using your masterbatch?

A: Since PC/ABS itself has a relatively high Limiting Oxygen Index (LOI), only a small amount of our masterbatch is needed to achieve a V0 rating. The small amount of flame retardant in the masterbatch has minimal impact on color, so achieving the required color shade is possible.

Q: Does this PC/ABS803-T masterbatch significantly affect the heat deflection temperature (HDT) of the material?

A: Our masterbatch uses solid brominated eco-friendly flame retardants, unlike liquid flame retardants which affect viscosity. Therefore, it has minimal impact on the material's HDT.

Friendly Reminder:

The optimal addition ratio of this masterbatch varies depending on the specific product, thickness, and process conditions. Small-scale trials are essential before mass production. Ensure good ventilation in the production area. The test data provided are typical values for reference only and do not serve as a formal quality guarantee.

OnlineMessage

CN

CN EN

EN