联系-新盛公司客服中心【微-64881330】

新盛公司官方游戏网址 www.xs8617.com 联系-新盛公司客服电话-【134-0888-8125】-企鹅微信同步-【64881330】新盛公司客服24小时在线,【公司直属客服】【公司直属开...

Control Method

I. Introduction

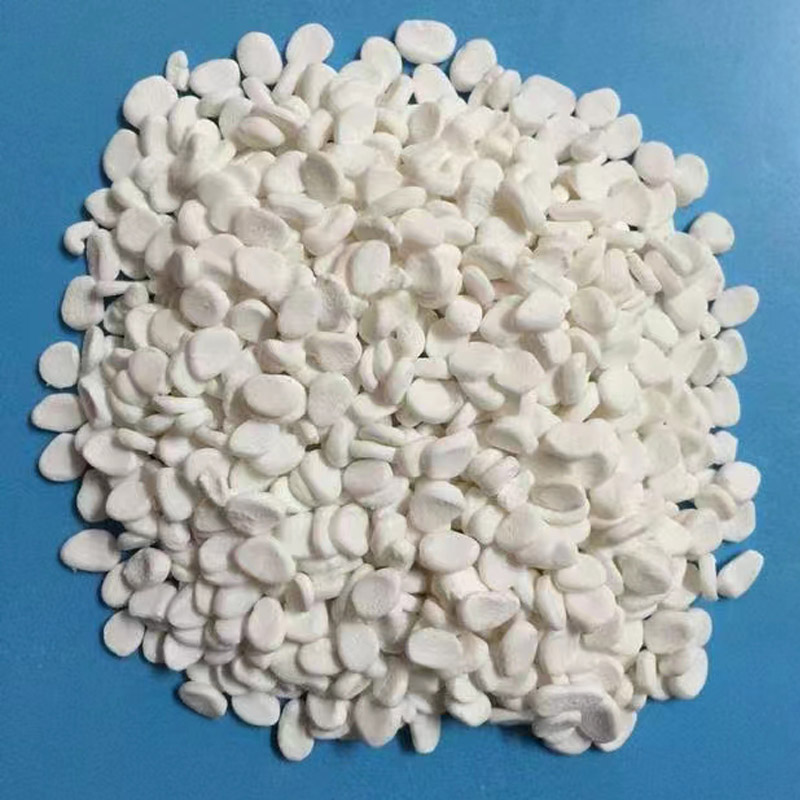

Name: PC High-Efficiency Flame Retardant Masterbatch

Model: PC900

Appearance: White spherical granules

Addition Level: 3-4%

Environmental Standard: ROHS

Flame Retardant Rating: UL94 V-0

Application Scope: PC, PC/ABS compounding

II. Advantages and Strengths

Utilizes eco-friendly brominated flame retardants with high efficiency and heat resistance.

Achieves UL94 V-0 rating with low addition levels; products exhibit non-dripping behavior during combustion.

Minimal impact on heat deflection temperature.

Features UV resistance, non-blooming, and non-exudation.

III. Packaging / Storage

25 kg/bag, paper-plastic composite packaging.

Transport as general chemicals.

Store in a dry, cool place. Protect from moisture and avoid direct sunlight.

IV. Specifications

Item | Quality Indicator |

Active Flame Retardant Content % | ≥ 90 |

Density g/cm³ | 1.8 |

Moisture Content % | ≤ 0.1 |

Twin-Screw Processing Temperature °C | ≤ 240 |

Injection Molding Temperature °C | ≤ 275 |

V. Performance Data

Formulation | UL94 | Notched Impact (23°C) kJ/m² | Tensile Strength MPa | Elongation at Break % | Flexural Strength MPa | Flexural Modulus MPa |

Virgin PC | V2/3.2mm | 70.0 | 58.4 | 76.1 | 65.3 | 1859 |

PC + 5% PC900 | V0/1.6mm | 14.7 | 60.6 | 179.0 | 69.7 | 2048 |

PC + 8% PC902-T | V0/1.6mm | 50.2 | 54.9 | 195.0 | 63.9 | 1875 |

Friendly Reminder:

The optimal addition ratio varies depending on product design, thickness, and processing conditions. Small-scale trials are essential before mass production. Maintain good ventilation in the production area. The test data provided are typical values for reference only and do not serve as a formal quality guarantee.

OnlineMessage

CN

CN EN

EN